Join us online

Supply chain network design implies finding optimal locations for new facilities (distribution centers, warehouses, and production sites), defining the flows between them, and balancing costs. An optimal design is crucial for the supply chain to be reliable and cost-efficient, as well as to be ready to deal with supply and demand uncertainty.

It is also important to mention that supply chain network design is a continuous process. Supply chain network cannot be designed and implemented once and forever. New challenges and opportunities mean business is always changing. Success requires quick and informed decision making.

To deal with all these challenges, many interdependent processes inside and outside the organization must be considered, which makes the situation quite unpredictable. The task is complicated even more by the fact that the most commonly adopted tool, spreadsheet-based modeling, is often not capable of handling complex, interdependent, and time-related systems, such as supply chains. More powerful forecasting and analytics tools are needed.

That is why network design in supply chain management, with increasing frequency, is conducted using specialized supply chain network design software. This is a much more flexible and effective solution than spreadsheets. When planning a future network, and when optimizing one already in place, logistics network design software can provide all the necessary data for supply chain performance analysis and decision making.

To gain greater insight into network design and optimization, you can watch our webinar. In this webinar we demonstrate the best practices for locating facilities, balancing supply and demand, optimizing inventory levels, and more.

watch the webinaranyLogistix software brings together analytical optimization, the classic supply chain network design method, with dynamic simulation in one platform. Using anyLogistix and your operational data, you can build, analyze, and improve your network end-to-end.

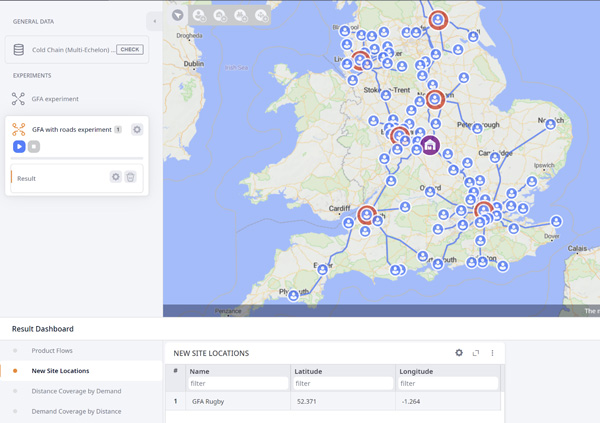

Greenfield analysis experiment in anyLogistix can be really useful in the first stages of supply chain network design. Using the minimum amount of input data, it will help to determine the optimal quantity of warehouses or production sites, and the best locations to place them. Unlike network optimization, Greenfield analysis does not need any options for facilities locations, the task of the analysis is to offer you these options from scratch.

Greenfield analysis is most often the first step in supply chain network design. It is used when you need to estimate quickly and roughly what the supply chain should look like. Greenfield analysis results are commonly used in further network optimization to determine the optimal configuration of the supply network to minimize costs.

Learn more about Greenfield analysis in anyLogistix>>

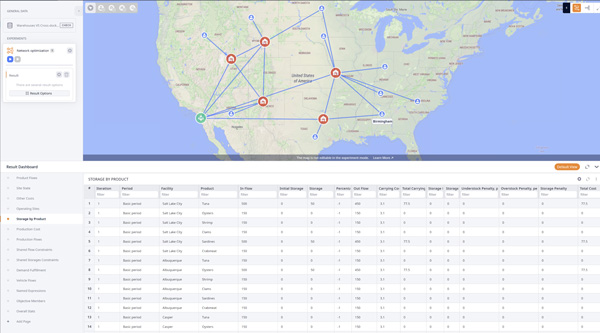

Supply chain network optimization seeks to find an optimal combination of production sites and distribution centers from the several pre-suggested. The solution should match supply and demand, as well as find a network configuration with the lowest costs.

anyLogistix software provides a suite of tools that enable informed decision making for supply chain optimization, including a demographic database. This helps locate new sites, depending on the population and customers' demand. The outputs of network optimization experiment will show optimal site locations, values of transportation and production flows, inventory at the end of each period, and associated costs. Furthermore, you will have data on all the possible network configurations options, including those with the lowest costs.

Learn more about network optimization>>

For a deeper dive into supply chain network design and optimization with anyLogistix, watch the following how-to video.

See how Deloitte used anyLogistix to design and optimize a supply chain for a major telecom provider — case study. Or learn more about applying anyLogistix to supply chain network design from the Supply Chain Digital Transformation white paper.