Interested in the FMCG distribution topic? Check out our blog post on FMCG inventory management, where we share best practices for strategic sourcing in the supply chain.

Companies producing and distributing fast-moving consumer goods (FMCG) operate in a dynamic environment characterized by demand uncertainties and seasonal fluctuations. FMCG distribution operators always need to balance cost efficiency with maintaining high service levels.

An international FMCG distribution company in Turkey faced a similar challenge. Due to market specifics, the transportation costs were too high, and growing market demand complicated its forecasting. The company wanted to review its existing policies and make strategic investment decisions. Together with Phoenix Analytics, they aimed to optimize the FMCG distribution network and improve supply chain demand forecasting.

Interested in the FMCG distribution topic? Check out our blog post on FMCG inventory management, where we share best practices for strategic sourcing in the supply chain.

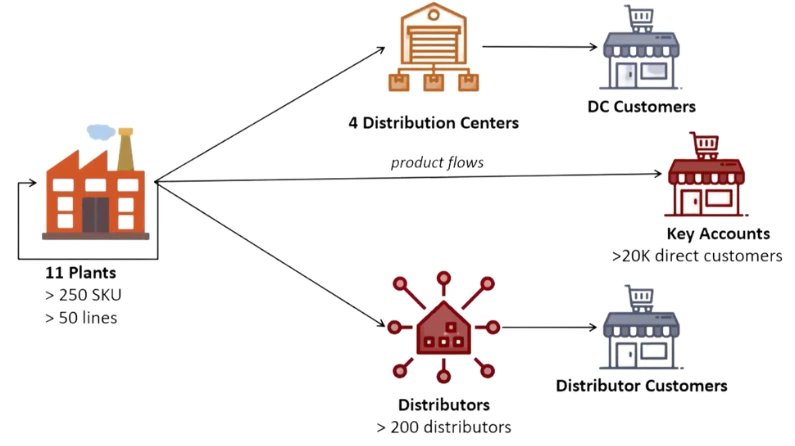

The international FMCG distribution company had a complex production and distribution network in Turkey, which included:

The structure of the company’s FMCG distribution network

The complexity of this distribution network presented a significant challenge for supply chain demand forecasting. Also, the company relied more heavily on road transport in its FMCG distribution network due to Turkey's limited rail infrastructure. This influenced the importance of finding the right policies to help cut down transportation costs.

The FMCG company also aimed to determine in what new facilities to invest. With sales growing quickly, it needed smart investments to meet demand without wasting resources. This required figuring out the best time and place to expand.

Phoenix Analytics used anyLogistix to create a digital twin of the client's supply chain. With this in place, consultants modeled various scenarios and delivered actionable insights.

The architectural solution for optimizing the FMCG distribution network integrated SAP, Excel, and Python to ensure seamless data flow and insightful analysis. Then, they used this data within the digital twin in anyLogistix for risk-free testing of different scenarios.

An architectural solution for FMCG distribution network optimization and supply chain demand forecasting

Thanks to this approach, the experts managed to:

Phoenix Analytics' innovative approach reduced the project's dependency on manual, Excel-based processes. anyLogistix played a crucial role in FMCG distribution network analysis and the definition of supply chain demand fulfillment strategies.

The project resulted in a 10% reduction in transportation costs for the international FMCG distribution company. Experts identified the optimal locations and timing for new lines and plants, ensuring a balance between cost efficiency and market readiness. They also evaluated inventory strategies, revealing the best solution to meet demand fulfillment criteria.

This project showcased the power of building a digital twin, which allows for effective scenario analysis and helps to balance supply and demand while minimizing costs.

This case study was presented by Ali Yoguran, Phoenix Analytics, at the anyLogistix Conference 2024.

The slides are available as a PDF.