Wolf GmbH, a German HVAC and solar technology provider, needed to cut transportation costs and CO₂ emissions in its European distribution network. The existing setup, centered in Munich with scattered DCs, lacked cost efficiency and strategic structure.

Rothbaum Consulting used anyLogistix to perform greenfield and network optimization analyses, testing scenarios from one central hub to multiple DCs across Europe. Demand was segmented by shipment type and volume, and cost models included transportation, processing, and facility expenses. Scenario testing identified the most efficient configuration.

Wolf GmbH is a leading system provider of heating, ventilation, and solar technology. It is based near Munich, Germany.

The company sought to optimize its European distribution network. With a global workforce of approximately 2,100 employees and a revenue of around 500 million euros in 2022, Wolf required a strategic network design concept for its European operations. This was necessary to optimize logistics and reduce costs in the supply chain.

Rothbaum Consulting Engineers GmbH, a technical consulting company specializing in operations management and strategy, led the project.

Wolf's existing distribution network is centered around its main plant in Munich, with additional distribution centers across Europe. Therefore, to improve efficiency and reduce supply chain costs, they needed a logistics optimization solution. The primary issues included high transportation expenses and the requirement for a strategic network design.

They wanted to answer key questions:

Rothbaum Consulting divided the project into seven work packages, with anyLogistix software playing a crucial role in the logistics optimization during the fourth and fifth.

Seven work packages for the supply chain cost reduction project (click to enlarge)

Rothbaum Consulting, after collecting all necessary data from Wolf and other stakeholders, built a project database using SQL and created PowerBI dashboards.

The next step was to conduct a greenfield analysis to find potential new locations for future distribution centers. They grouped customers by ZIP code regions and modeled their demand based on freight weight and the number of shipments, testing various scenarios.

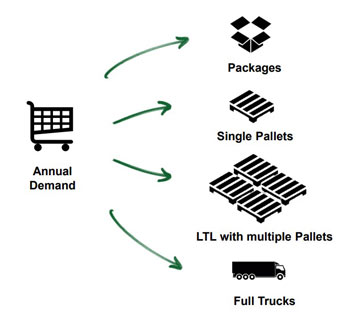

Logistics demand segmentation

and shipment modeling

The scenarios ranged from one main distribution center for all of Europe to several sites in different countries, ultimately identifying up to 100 potential locations.

In the strategic network design phase, Rothbaum Consulting developed several scenarios for the future network, estimating cost savings for each. To create a price function in anyLogistix for savings estimation, they broke down annual demand into shipment types and sizes, using existing transportation costs.

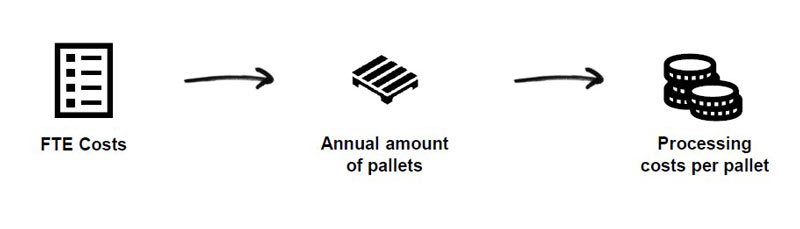

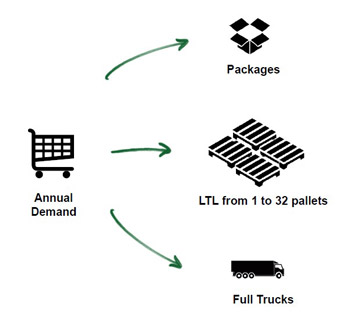

Moving to the tactical network design phase, the consulting company added detailed cost factors like processing costs per shipment and facility expenses. They refined calculations for less-than-truckload shipments and included key supplier locations to optimize shipments directly to distribution centers.

The main objective was to test different strategic network designs to find the best number of new distribution centers.

Calculating pallet processing costs from full-time equivalent expenditures

Segmentation of annual demand

into shipment sizes for less-than-truckload analysis

After thorough analysis and testing, Rothbaum Consulting found that adding one new distribution center in Germany would be the most effective logistics optimization strategy. This approach provided overall cost savings of 5–10%, depending on the scenario.

Additionally, the total driving distance in the network was reduced by approximately 35%. The reduction in driving distance not only lowered transportation costs but also reduced CO2 emissions.

The case demonstrates the importance of strategic network design in logistics optimization. Using data analysis, scenario testing, and anyLogistix, Rothbaum Consulting helped Wolf achieve a significant supply chain cost reduction and improved efficiency and sustainability in their logistics operations.

This case study was presented by Mark Smoliar, Rothbaum Consulting Engineers, at the anyLogistix Conference 2024.

The slides are available as a PDF.