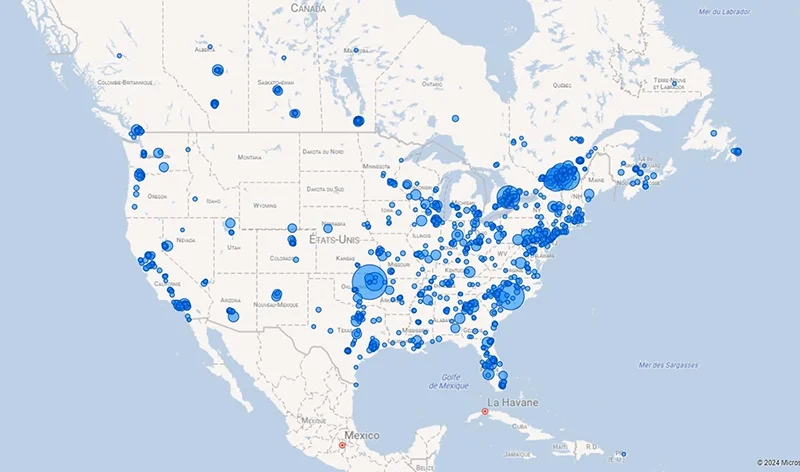

Efficient supply chain management is essential for industries with complex production and logistics needs. In this material, SimWell Consulting presented the case of their client—a leading North American pulp and paper company that produces recyclable packaging and paper products. The company operates about 70 manufacturing sites and has thousands of employees.

The spread of the client network

SimWell used anyLogistix supply chain software to develop a freight planning tool for integrated transportation planning and optimization.

The client set three main goals:

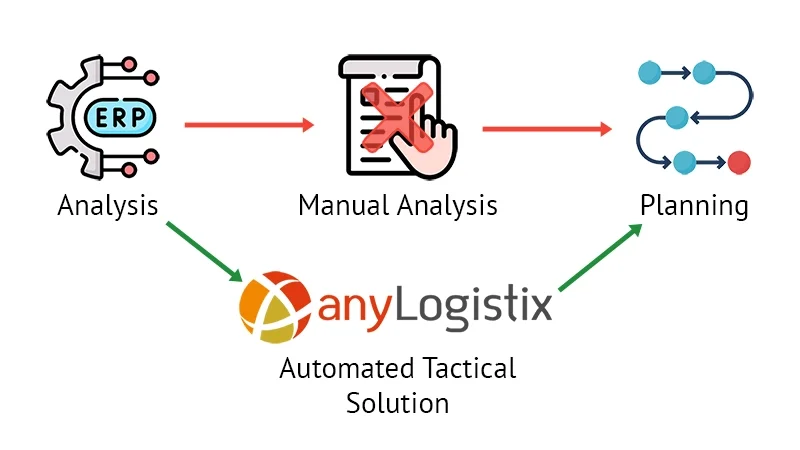

The existing decision-making processes were manual and time-consuming, which affected the company’s ability to remain competitive and slowed down the operations.

Shift from manual analysis to automation with a freight planning tool

The client strived for a data-driven solution to automate and implement the analysis as a freight planning tool. They wanted it to dynamically adjust to changing demands, costs, and external factors such as strikes or new regulations.

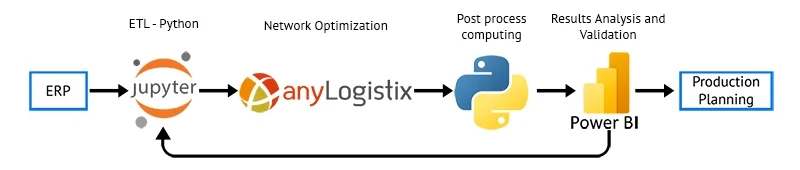

The solution involved developing a freight planning tool in combination with anyLogistix’s capabilities with the company’s ERP (Enterprise Resource Planning) system. The project focused on freight transportation planning and route optimization. The consultants wanted it to determine the best production locations and transportation methods. Key technical elements included:

The scheme of data circulation within the freight planning tool

With a custom ETL (Extract Transform Load) tool, SimWell extracted data from multiple databases, including manual inputs and electronic databases. The tool structured information and prepared it for use in anyLogistix.

Read also: To learn about data integration, read our blog on building a digital twin with anyLogistix API.

The consultants addressed unique business constraints using Big M and mathematical formulations in anyLogistix.

The Big M method is a linear programming technique for handling constraints with inequalities by introducing artificial variables.

The flow for using it in the project consisted of two steps:

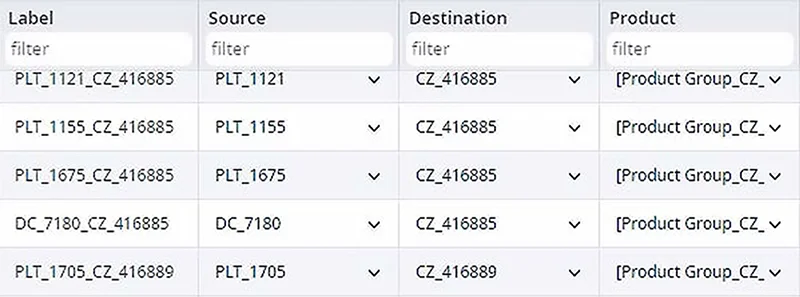

Implementation of the custom constraint in anyLogistix

The constraints ensured that customers sourced at least 36,000 units from multiple locations and limited customers to sourcing a product from only one location.

With the previous stages succeeding, SimWell developed a freight planning tool that showed the cut in data processing time from 8-12 hours to 4 hours. The automation allowed for faster validation and implementation of the analysis results.

SimWell visualized the results using Power BI. This tool helped experts rapidly see, consider, and apply the findings to production and transportation planning and optimization strategies.

Read also: Another SimWell case study showcasing the use of anyLogistix to translate greenfield analysis results into network optimization, with the outcomes visualized with Power BI.

The project led to significant improvements in the company’s transportation planning and optimization:

Once the case showed promising results, the company decided to pursue perfection, so SimWell came up with several ideas using anyLogistix. Among them are further automation of data structures, deeper analysis of CO2 emissions, and the integration of digital twins across all divisions to enhance overall supply chain resilience and synergy.

This case study was presented by Mathieu Bédard, Ershad Jahagirdar, and Jean-Daniel Mathieu from SimWell at the anyLogistix Conference 2024.

The slides are available as a PDF.