ALX Sandbox is a click away

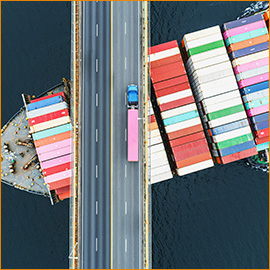

Explore the future of supply chain management with our latest blog post on the top 5 trends for 2024. Learn how artificial intelligence, digitalization, and platforms like anyLogistix are revolutionizing the way supply chains are managed, which makes them smarter, sustainable, and stable.

Read more

As we step into 2024, it's the proper time to have a final glance at 2023. This blog post sums up the highlights of the past year, including new releases, the anyLogistix Conference 2023, webinars, blog posts, and case studies.

Read more

In this blog post, you'll explore the world of digital twins, focusing on the future of digital twin technology and its role in the supply chain. Moving beyond simple simulations, digital twins combine data visualization, technology, and analytics to improve decision-making. This system evolved from basic to intelligent digital twins, where they can create new knowledge. Knowledge that will help you deal with unpredictable challenges.

Read more

In the latest version of our supply chain design and optimization software, we enhanced the user experience by adding multi-user access to projects, expanded functionality with a new API, and improved performance. Read on to learn more about what's new in anyLogistix 3.1.

Read more

In today's business environment, adaptability and flexibility are not just virtues, they are necessities. In this blog post, we'll unpack the revolutionary floating license - an adaptable solution for dynamic businesses - and explore anyLogistix Floating Licensing options available for your business needs.

Read more

This blog post showcases the video presentations from this year’s anyLogistix conference. From expert speakers to innovative solutions, the videos cover a wide range of topics, including supply chain optimization, digital twins, and our latest update. These presentations provide valuable insight for both professionals and newcomers in the logistics industry.

Read more

The FMCG sector operates in a highly dynamic environment. Failure to keep up with the advancements can result in being outrun by competitors and falling behind in the industry. With an overview of the most frequent challenges consumer-goods companies face, we’ll explore the solutions and illustrate them with business examples from the industry leaders.

Read more

To design a profitable and resilient logistics network, you need to determine where to locate distribution centers, warehouses, and production sites, find the optimal network configuration, and stress-test it with simulation. With a simple 3-step example, this blog post will guide you through the whole process.

Read more

The first anyLogistix Conference gathered over 300 supply chain modeling practitioners from various industries to share the best practices in supply chain digital transformation. Check out the brief overview of the themes and projects that were presented.

Read more

In the wake of COVID-19 and widening geopolitical risks, companies around the world are aiming for supply chain agility, resilience, and efficiency, but how can they achieve these? In this blog post, you’ll learn about current supply chain risks, what constitutes an agile and resilient supply chain, and how to achieve that through digital transformation.

Read more