The Fast-Moving Consumer Goods (FMCG) industry holds a prominent position in the global market, touching various aspects of our daily lives. From using personal care products during a morning shower and eating cereal for breakfast, to snacks and drinks at local pubs, our lives revolve around consumer goods.

The FMCG sector operates in a highly dynamic environment where both products and processes evolve rapidly. Failure to keep up with these advancements can result in being outrun by competitors and falling behind in the industry.

Supply chains play a vital role in FMCG. If there were ever any doubts, the significance of supply chains in this sector became clear during the initial stages of the Covid-19 pandemic when empty shelves, once filled with toilet paper and toothpaste, served as a stark reminder. To ensure the supply chain runs efficiently, managers need to be aware of the potential pitfalls and challenges.

In this blog post, we will give an overview of the major issues consumer goods supply chain managers face and explore possible ways to solve them. They are illustrated with two case studies from the FMCG industry leaders.

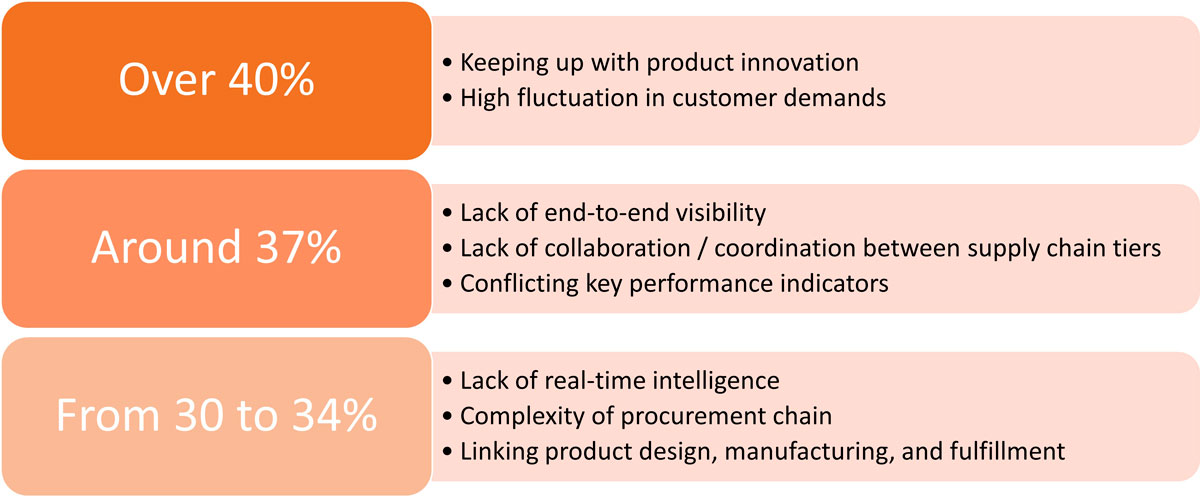

According to The Economist, supply chains face a lot of challenges, with demand volatility and product innovations being the most frequent of them.

Main challenges that FMCG supply chains are facing according to The Economist

Additionally, FMCG supply chains are immensely complex with a great number of distribution centers, factories, SKUs, and millions of customers. Therefore, they are difficult to manage and change.

Before Covid-19, consumer-goods companies were rapidly expanding to capture shelf space and niche markets. This complexity has now become a vulnerability, demanding a return to basics. Some companies have worked closely with their customers and suppliers to simplify their portfolios and increase availability of high-volume items.

Because of the complexity, FMCG supply chains are also subject to disruptions. Supply chain disruption comes in many forms: from local issues such as a staff shortage or a warehouse fire, to global problems like the COVID-19 pandemic, or even events like the 2021 Suez Canal obstruction. The question supply chain managers ask is how best to manage it or prevent it from happening in the first place.

Yesterday everyone was going crazy about acai berry, today matcha madness is spreading widely. There’s always something that suddenly sparks the interest of the masses. It means volatility for FMCG – with demand surging in one place and plummeting in another. And with complexity being an integral part of consumer-goods supply chains, most companies aren’t set up for agility.

Inaccurate estimation of demand can result in overproduction or in extra long lead times that might cause financial loss. Overproduction results in surplus inventory, ties up capital, and increases storage costs. On the other hand, extended lead times can lead to customer dissatisfaction, lost sales, and the potential loss of business opportunities.

FMCG companies face intense competition, and product innovation helps them stand out from their competitors. By introducing innovative products that offer unique features, improved functionality, or better value for consumers, companies can differentiate themselves in the market and gain a competitive edge.

Developing innovative products often requires collaboration with suppliers, research organizations, and technology partners. By engaging with these stakeholders, consumer-goods companies can leverage their expertise, resources, and technological advancements to bring innovative products to market. Collaboration also helps in overcoming technical challenges and reducing time to market for new products.

Product innovation also influences the design and management of supply chains. For example, the introduction of new product variants or categories may require adjustments in sourcing strategies, production processes, packaging materials, and distribution networks. FMCG companies need to ensure that their supply chains are agile and flexible enough to support the quick delivery of innovative products to the market.

To optimize supply chain design and operations, managers apply digital technologies. At the organization level, this means utilizing analytics, artificial intelligence, robotics, IoT, and other advanced technologies to collect and process information automatically and support decision making.

Among such tools that FMCG companies use to evolve and stay competitive are simulation and optimization. A couple of examples below illustrates how businesses leveraged these technologies to their benefit.

Coca-Cola HBC is one of the largest investors among consumer-goods manufacturers. The company wanted to improve its distribution network in one of the CIS countries. To cut storage, transportation, and delivery costs, and optimize logistics across the country, the company’s management decided to create a digital model of the current supply chain.

The model developed in anyLogistix supply chain optimization software turned into a decision support system. Now it helps Coca Cola HBC test numerous hypotheses on changes in the logistics and production strategies in a few hours.

As an output, the company’s supply chain managers can get a new supply chain configuration, the required number of vehicles, and their optimal load. So, they can choose the most profitable points for direct delivery relying on detailed calculations of expenses for each store on the network.

A multimillion FMCG company saw their presence in markets such as Southeast Asia as an important contribution to their consistent and continued growth. However, the company used a logistics network design and inventory policy that could not support the demand in that region and wasn't efficient enough.

To avoid financial losses and a negative effect on their regional operations, the company’s management built a digital model of their supply chain in anyLogistix software, then used its simulation and optimization capabilities to experiment with the network design and test new inventory policies.

The final design and policies, compared to the baseline design, showed better performance in terms of service level and cost saving. The average inventory level was reduced by 35% and total costs decreased by 20%. The proposed network design structure was presented to the company’s executives and was advised for implementation.

With numerous challenges related to constant demand fluctuations, high competition, and supply chain complexity, consumer-goods companies need the insights and tools at hand to react and adapt quickly to stay afloat.

First, start with identifying the problems and then take a holistic approach to solve them. A problem in the upstream part may cause disruptions to the downstream one, and the other way around, so understanding the interdependencies as a first step is the key.

Following the preliminary analysis, a digital model of a supply chain developed in anyLogistix supply chain design and optimization software will help test assumptions and experiment with the changes until the optimal solution is found. Now there’s data that can back managerial decisions and ensure an FMCG company is profitable and stays ahead of the competition.