Decision Lab, a renowned UK technology company, specializes in applying intelligent solutions to complex business challenges. In a recent project, they partnered with a confidential enterprise, hereafter referred to as the "FMCG client" due to sensitivity concerns.

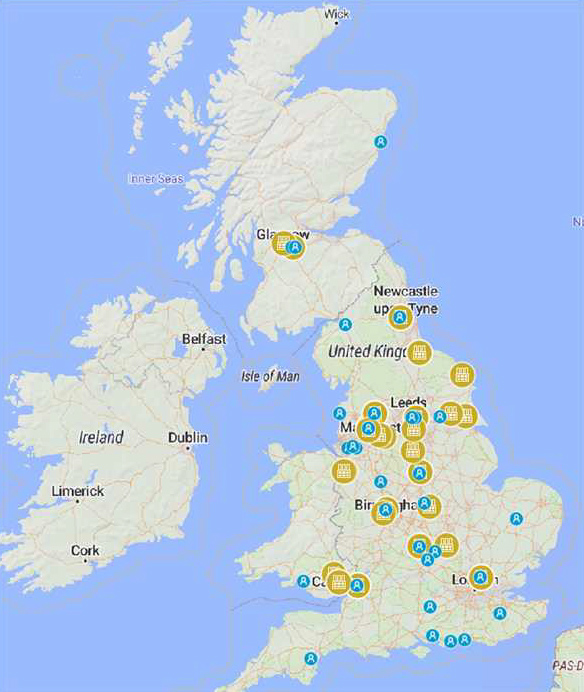

Map of customer and bakery

locations in the UK

The FMCG client is a well-known UK manufacturer of baked goods. The client wanted to perform supply chain modernization with a distribution system consisting of 10 bakeries, each linked to a primary warehouse. In addition, there are 40 secondary warehouses, some of which are stand-alone, serving as final distribution points for retailers.

While this complex system underscores the client's vast reach, it also brings logistical challenges, especially given the perishable nature of its products.

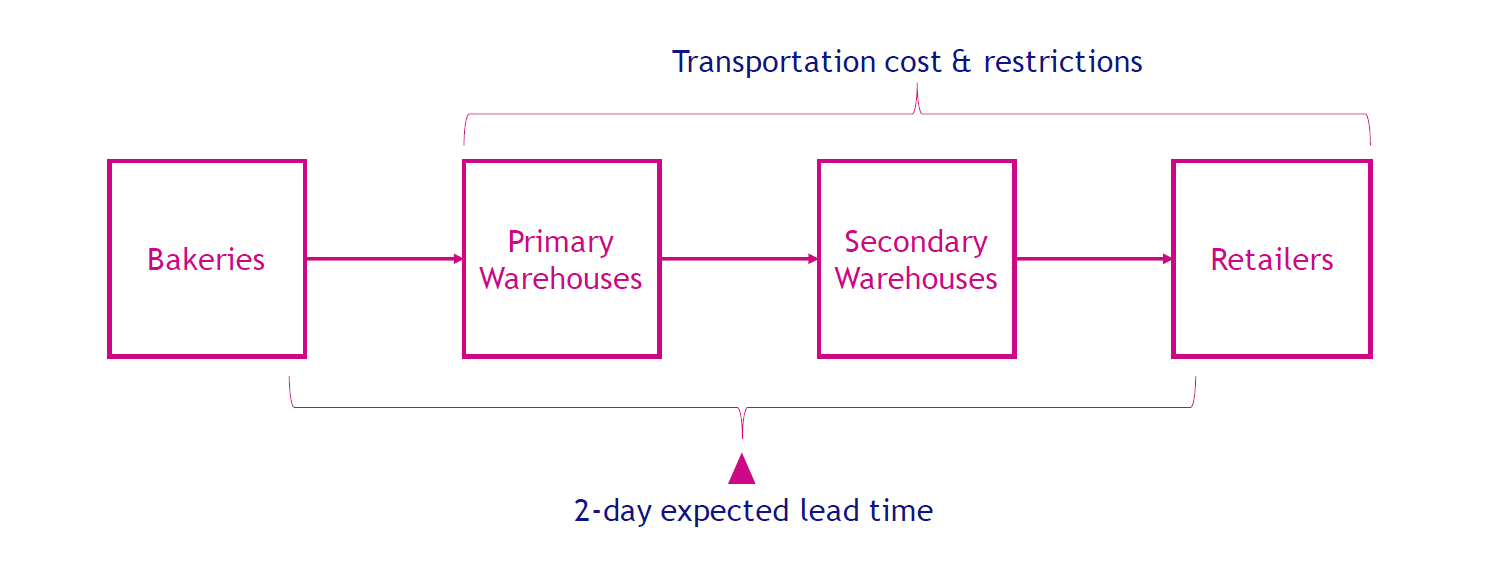

The Fast-Moving Consumer Goods (FMCG) industry is known for its ever-changing requirements. In this environment, the FMCG client constantly needed to keep up with the times, especially when dealing with perishable goods that have a limited shelf life. The client needed to distribute its products within a two-day time frame. This in turn required not only the necessary number of vehicles ready for distribution but also sufficient space to safely store these goods.

Client’s supply chain flowchart

However, the FMCG client's data was scattered across multiple platforms, and the need for supply chain modernization became evident as the primary tool for supply chain modeling was Excel. This approach resulted in limited insights, which caused operational inefficiencies and restricted potential growth. In addition, the client's reactive approach to demand management was slowing its progress toward cost reduction and increased flexibility.

To address the FMCG client's operational challenges, Decision Lab conducted a series of workshops that drew insights from various departments, including production, warehousing, and logistics. During these meetings, it became evident that the client needed a single software platform like anyLogistix to design, analyze, and optimize its supply chain network. By using anyLogistix, the team sought to perform supply chain modernization and gain a clearer understanding of its operations.

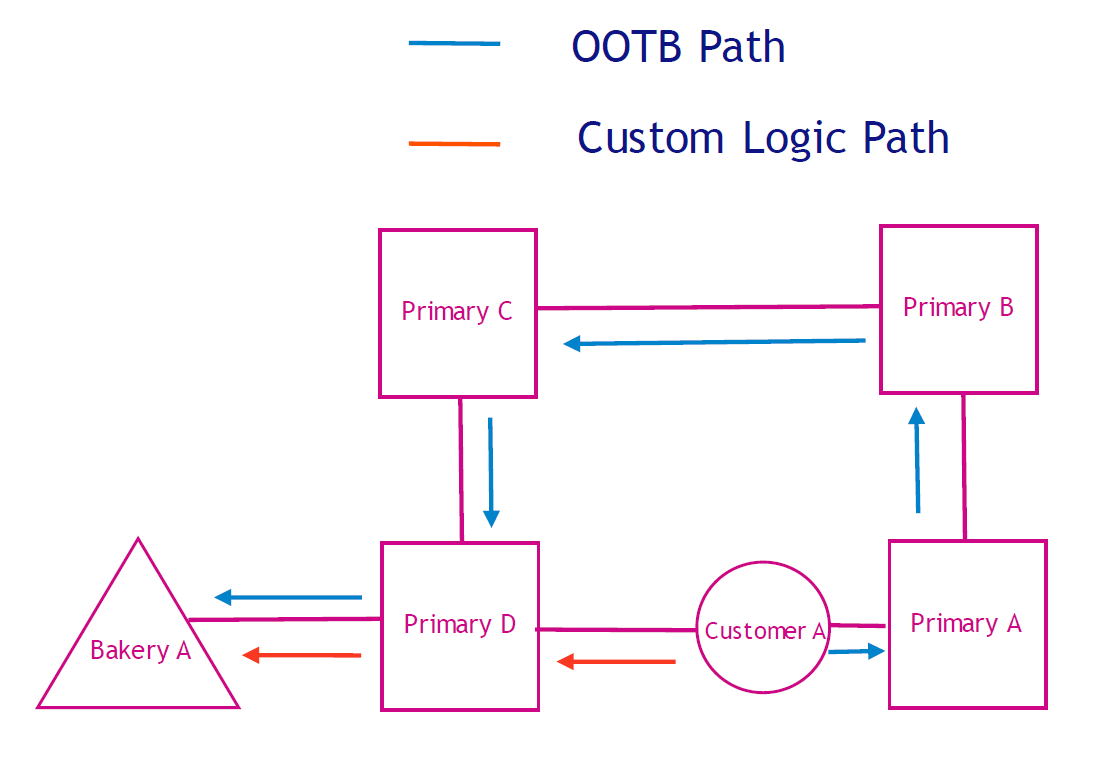

While Decision Lab effectively addressed most challenges using the capabilities of anyLogistix, some client-specific needs required tailored solutions. The team used the software's extension editor, powered by the AnyLogic simulation engine.

The goal was to adjust entities within the network, like distribution centers and factories, and edit process flows for each. This allowed Decision Lab to modernize their supply chain and fine-tune the software to the FMCG client's unique network, aiming to improve logistics efficiency.

In this project, Decision Lab used anyLogistix's out-of-the-box capabilities. Additionally, they developed key custom features such as production and bakery logic, SQL database outputs, resource utilization, and product sourcing logic.

For example, they designed a system to measure staff impact on vehicle loading and unloading times. The team also segmented the bakeries based on production capacity, ensuring each product was produced within the available resources. In addition, Decision Lab used the JDBC (Java Database Connectivity) library to send data directly to an SQL database and visualize it on a Power BI dashboard.

Pathway diagram: out of the box vs. custom logic

By focusing on product sourcing logic and aiming to improve logistics efficiency, the team determined the optimal sourcing location for each customer and warehouse. Decision Lab developed a special-order subclass that preserved the origin of each product, ensuring it was produced for specific requests rather than general inventory. In all their efforts, the team demonstrated an adaptive approach to achieve supply chain modernization and develop solutions that met the FMCG client's unique needs.

Decision Lab undertook a project to modernize a client's workflow, integrating anyLogistix. By transitioning from a scattered Excel-based system to a centralized one, the client gained deeper insights into its supply network, enabling data-driven decisions.

Introducing Power BI dashboards was a game-changer, offering deep insights into inventory levels, staff utilization, and queuing times. This granularity, achieved at intervals as short as 10 minutes, proved invaluable. It empowered the FMCG client to make informed decisions.

Outbound comparison between scenarios that have been executed

(click to enlarge)

Previously, the FMCG client had optimized product placements and addressed storage inefficiencies by relying on intuition rather than hard data. Now, with robust analytics, they could confirm and refine these strategies, ensuring their effectiveness with solid evidence.

In conclusion, Decision Lab's integration of anyLogistix and further enhancements have significantly improved logistics efficiency in the client's supply chain processes. The combination of advanced tools and centralized data management has positioned the FMCG client for a future marked by resilient and efficient supply chain operations.

This case study was presented by Adam Coleman and Jacob Whyte from Decision Lab at the anyLogistix Conference 2023.

The slides are available as a PDF.